We are your eyes in supply chain

Quality Inspection Services

What is quality inspection?

Quality inspection, also called quality control (QC), is a procedure or set of procedures intended to ensure that a manufactured product or performed service adheres to a defined set of quality criteria or meets the requirements of the client or customer.

As the product quality is the competition key on the market, more and more importers and buyers, especially the international brands, request systematically the quality inspection for their orders in China.

Nowdays, in order to have a stable quality and reduce the defective rate during the mass production, most clients choose also the During-Production-Inspection (DPI), which is really the best solution to avoid the bad surprise just before the shipment.

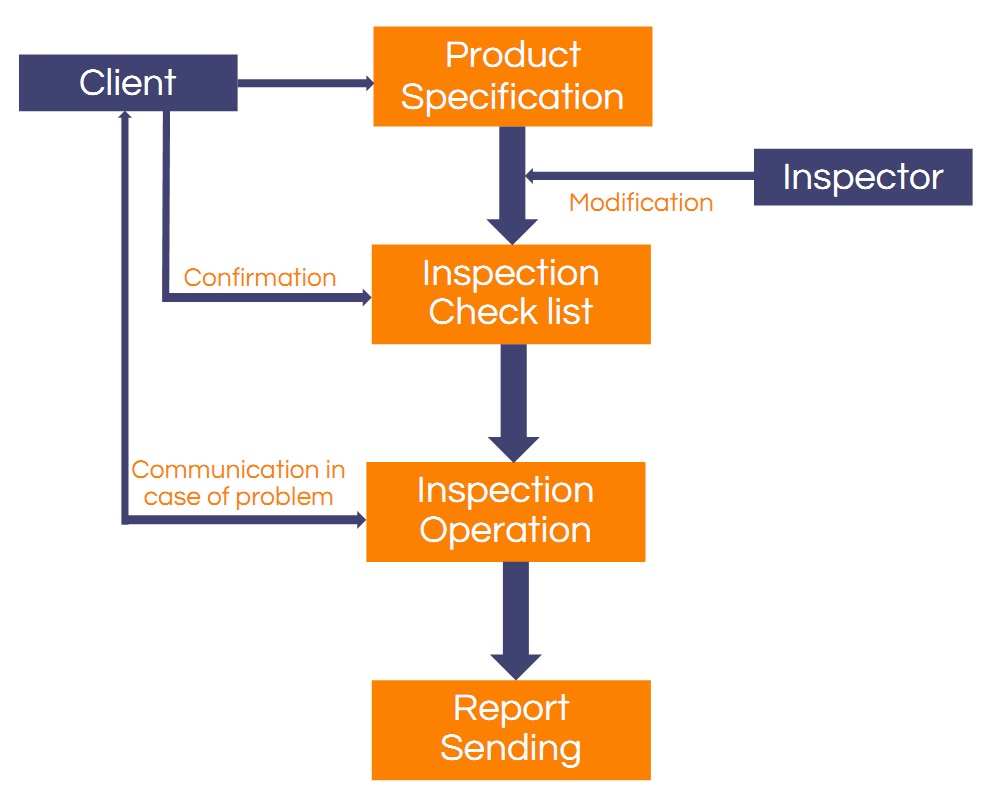

Quality inspection procedure

In order to carry out an objective and efficient quality control operation, INSPECTION-CHINA has established an effective procedure which standardized the actions of each Inspector.

Before the quality control operation, we will send also the inspection standards to the supplier so that he could be aware of all the important points and try to reduce the defective products during the production.

Types of quality inspection services

INSPECTION-CHINA proposes always various options of quality inspection services to our clients. We can organize quickly the requested quality control intervention onsite according to the client’s instruction.

All the inspection report with photos or videos will be sent to the client within 24h after the operation. In case of problem, our inspector will contact directly the client during the quality inspection.

Pre-Production Inspeciton (PPI)

The Pre-Production Inspection (PPI) is an important step to make sure if supplier respect all the specifications and requirements before the beginning of mass production. This inspection will be realized during the preparation of mass production. The supplier could start the mass production once the result is positive.

During Production Inspeciton (DPI)

The During-Production Inspection (DPI) is an important monitoring step which allows you to follow closely the status of production and make sure that all the requiremets and intrustions are respected by the supplier. Usually, this inspection will be realized when 20%–25% of production is finished.

Pre-Shipment Inspeciton (PSI)

The pre-shipment inspection (PSI) is the final inspection made on the finished and packed products before the shipment. According to the request of client, this inspection will be realized usually on 90% - 100% finished and packed products. Usually, the client will make a desicion after the reception of report.

Container Loading supervision (CLS)

The container loading supervision (CLS) is a shipment control service by which we will monitor the whole loading process from the arrival of container to the container closing seal. During this operation, the container loading information will be recorded in detail which could avoid the bad suprise at goods reception.

Main checking points during inspection

- Pre-Production Inspection

- During Production Inspection

- Pre-Shipment Inspection

- Container Loading Supervision

– Order information (reference, quantity, raw material, components, packaging,…)

– Production organization (schedule and processes)

– Supplier internal quality control

– Inspection of samples before mass production

– Fonctional test of product if request

… …

– Production status and leadtime

– Production process

– Internal quality control

– Inspection of mass production samples

– Problems met by production team

– Storage of finished products

– Other important detail requested by client

... ...

- Appearance: cleanness, in good condition, color, workmanship, ...

- Product technical points

- Product function, safty, ...

- Carton dimension, weight, quantity, ...

- Logo, legal information, label, manual, ...

- Packing, protection, packaging, shipping marks, ...

- All other special requirements of client

... ...

- Damaged cartons

- Damamaged goods

- Wrong loading quantity or cartons missing

- Wrong loaded references or cartons

- Disordered loaded cartons or references

- Non-optimized loading space

... ...